Not all Upper Control Arms (UCAs) are all made equal. You have the option to pick from options like billet and tubular, with a wide range of joint types like heims, uniballs, and ball joints. With a no compromise approach to price and performance JBA has hit a sweet note for strength and comfort.

If you haven’t heard of JBA Offroad, they’ve been making control arms for the Toyota community for a long time. In fact, it’s been their primary focus. They cover many makes and models, even beyond Toyota. They have a killer reputation for quality and customer service.

So when it was time to upgrade, I decided to go with their HD version. These arms fit the 2005-2023 Tacoma. Let’s dive in!

Quick Features & Specs

- American made/sourced steel

- Vibrant red power coat finish

- Easily replaceable, high range of motion ball joints

- Greaseable inner pivots with upgraded bushings (patented channels with relief valves)

- Works with most (pretty much all) lift kits

- High caster and very strong design

- Standard (more budget friendly) option also available

- Made for 1-3.5″ of lift

- 365-day return policy (very unique)

- Lifetime warranty!

Table Of Contents

HD UCA VS. Standard UCA

JBA offers three different types of upper control arms for the Tacoma, one of which is designed for a 4-12 inch lift. For this comparison, we’ll exclude the last option and focus on the standard length upper control arms.

Both versions feature the standard 90-degree motion, heavy-duty, easily replaceable, and greaseable ball joints. Another standard feature is the patented EZ Lube bushings, which have channels and relief holes that allow grease to flow to the outside. Additionally, compared to the stock arms, these control arms offer three more degrees of caster, which helps accommodate larger tires.

The key difference between the HD version and the standard version lies in the gussets and thicker tubing. On the bushing side of the arms, the HD version has a full gusset that wraps around the arms and is welded to the bushing tube. Furthermore, the tube used for the HD version is closer to 3/8 inches thick, compared to the standard version, which is 1/4 inch thick.

Find Them Online

- HD UCA: Check Price

- Standard UCA: Check Price

Install Guide

Tools & Materials

- Jack and jack stands

- Socket set and wrenches

- Torque wrench

- Impact wrench (optional)

- Breaker bar (for tough bolts)

- Pry bar

- Needle nose pliers (for cotter pins)

- Penetrating oil (like PB Blaster)

- Safety glasses and gloves

Step 1. Prepare & Lift Truck

Park your Tacoma on a flat, level surface. Set the parking brake and wear your safety gear.

Loosen the lug nuts (lightly) on the front wheels while the vehicle is still on the ground. Using a jack, lift the front of the truck and secure it with jack stands. Make sure the vehicle is stable before proceeding. Remove the front wheels.

In this example we are using a lift at Stellar Built, so our process is a little different.

Step 2. Remove Old UCA

Disconnect the sway bar link and swing the sway bar down and out of the way. Next, disconnect the ball joint from the spindle. You may need to tap the steering knuckle with a hammer to loosen the ball joint if it’s stuck. A ball joint separator or pickle fork may help here as well.

Remove the main pivot bolt. These longer bolts have a tendency to run into the inner fender wall. Use long plyers to bend the sheet metal to create clearance to remove the bolt.

Remove the stock arm. You might need to tap the arm with a hammer if it’s stuck in place.

Step 3. Install New UCA

Now it’s time to get the new arms installed. Simply put, you’re just going to do the previous steps in reverse.

To quickly summarize, install the long pivot bolt first. Then connect the ball joint to the the spindle. Ensure everything is torqued to spec. Reinstall your sway bar links if you disconnected them.

Step 4. Reinstall Wheels

Put the front wheels back on and hand-tighten the lug nuts.

Carefully lower the truck back onto the ground using your jack. Once the truck is safely on the ground, torque the lug nuts to the manufacturer’s recommended specification (usually around 85 ft-lbs. for Tacoma).

Step 5. Check All Bolts

After the installation is complete, double-check all bolts to ensure everything is tightened to the proper torque specifications.

Inspect the area to make sure everything is secure, and nothing is rubbing or misaligned.

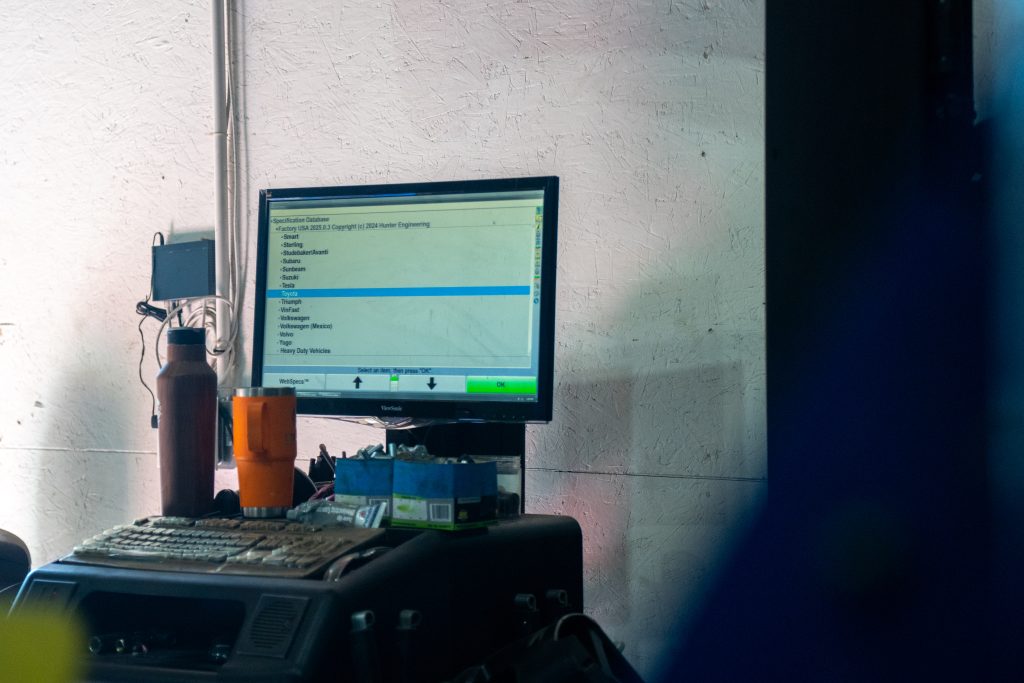

Step 6. Get An Alignment

Since you’ve changed the geometry of your suspension, it’s a good idea to get a professional wheel alignment to ensure the truck drives correctly and the tires wear evenly. It is recommended to get a dedicated offroad shop to align the vehicle as dealerships and random shops often don’t have the right experience for lifted applications.

Review

The overall quality of the JBA upper control arms is excellent. The heavy-duty reinforcements they’ve added work well with the truck’s weight, especially when paired with the upper arm double shear kit we also installed. The easily replaceable ball joint (no need for a press) is a fantastic feature, and I trust that these well-designed bushings won’t squeak like most of the polyurethane bushings available on the market.

Other than that, the installation was straightforward, and the truck is now equipped with a setup that should offer excellent reliability and performance on the trails ahead. Stellar Built, my local off-road shop that offers alignments, had zero issues getting things aligned and the arms gave us more than enough caster.

It’s been several thousand miles of on an off pavement use, and I’m happy to report that everything is holding up well. The steering and front end feel super solid. Joints are tight, no noises, no premature wear. These should hold up for quite a while! And given their lifetime warranty and robust return policy, you can clearly see they stand behind their products.

Don’t forget… JBA recommends greasing these every 3,000-5,000 miles to ensure longevity and prevent noise.

Final Thoughts

After putting a thousands of miles on these control arms, I am extremely pleased with them. From the elimination and prevention of front end noise (squeaking, etc.), to better handling and perfect alignment specs.

The arms perform smoothly and quietly. They feature greaseable fittings and other components that make them easy to service. These arms should be maintained during every oil change, and for optimal performance, the ball joint should be greased with lithium complex grease fortified with moly.

Overall, JBA is delivering a high-quality product that is easily serviceable at home, making it a great option for the everyday weekend warrior.