It’s been about 3 years, and the Meso Customs 3rd Gen Tacoma has finally left Stellar Built in Sacramento. If you’re a regular down at the shop, or familiar with Meso in general then you know the build. For the first couple of years down at the shop, the build wasn’t making a ton of traction.

In the last year, the build has been a dedicated focus for SEMA 2024. CJ, aka Cadillac Jones, was the lead fabricator on the build. It’s been CJ’s daily project for the last year and it’s taken shape quickly since CJ has been on it.

At A Glance

If you’re not familiar, I’ll get you up to speed.

The HellTaco is an absolutely insane 3rd Gen Tacoma 4×4 prerunner build with a Hellcat crate engine mated to a Torqueflite eight-speed automatic transmission and Behemoth NP205 Colossus transfer case. The front-end suspension is a 4.5″ extended Solo Motorsports Bronco Twin Traction Beam (TTB) with RCV axles, KING 2.5″ coilovers, and 3.0″ 4-tube bypass secondaries pulling about 17″ of travel. The rear is a Solo Motorsports Tacoma triangulated 4-link kit with Solo Motorsports trailing arms connected to a Currie Fab 9″ housing running a Strange Engineering Ford 9″ 3rd member with 4.56 gears spooled, Currie 40-spline shafts and pulls about 26″ of travel. The interior roll cage, motor cage, core support, and the back half were designed and fabricated around 2″ .120 wall DOM, and the secondary supports are a mix of 1.5″ and 1.75″ .120 wall DOM.

We covered a post on the previous version of his build; the long-travel twin turbo setup. That version of the build will never be seen again. There is very little left of what was once a 3rd Gen Tacoma. The only thing “3rd Gen” left on the build is the cab and a small section of the factory frame rail. The rest of the build has been deleted.

Will It Make SEMA 2024?

I wanted to give you guys a breakdown of the build before it’s finalized and makes the SEMA 2024 deadline. Stew has an insane amount of work to do; fiberglass hood, fenders, body panels, electrical, all the plumbing for the motor, and anything that requires a line in addition to the entire interior.

Given the level of detail we’ve seen in other versions of the build, we’re pretty excited, to say the least, to see how the build will take shape. Good luck Stewart, you have a lot of work left.

Find Them Online

- Meso Customs: Instagram

- Stellar Built: Visit Website

- CJ Moody: Instagram

Table Of Contents

Video Overview

Motor & Trans

The HellTaco will be running a 6.2-liter supercharged V8 from a 2018 Dodge Hellcat mated to a Torqueflite eight-speed automatic transmission. Currently, it produces 707 hp out of the crate, but Stewart aims to boost it to 800-900 hp with an E85 conversion, a custom tune, new intake, headers, and a port and polish of the factory supercharger. Knowing Stewart, he will probably take the supercharger off and boost it with something bigger down the road.

T-Case

The transfer case is a Behemoth fully geared NP205 colossus, specifically a Billet NP205 Replacement Case. Sacramento Driveline will provide custom-made driveshafts for both the front and rear.

Twin Traction Beam (TTB)

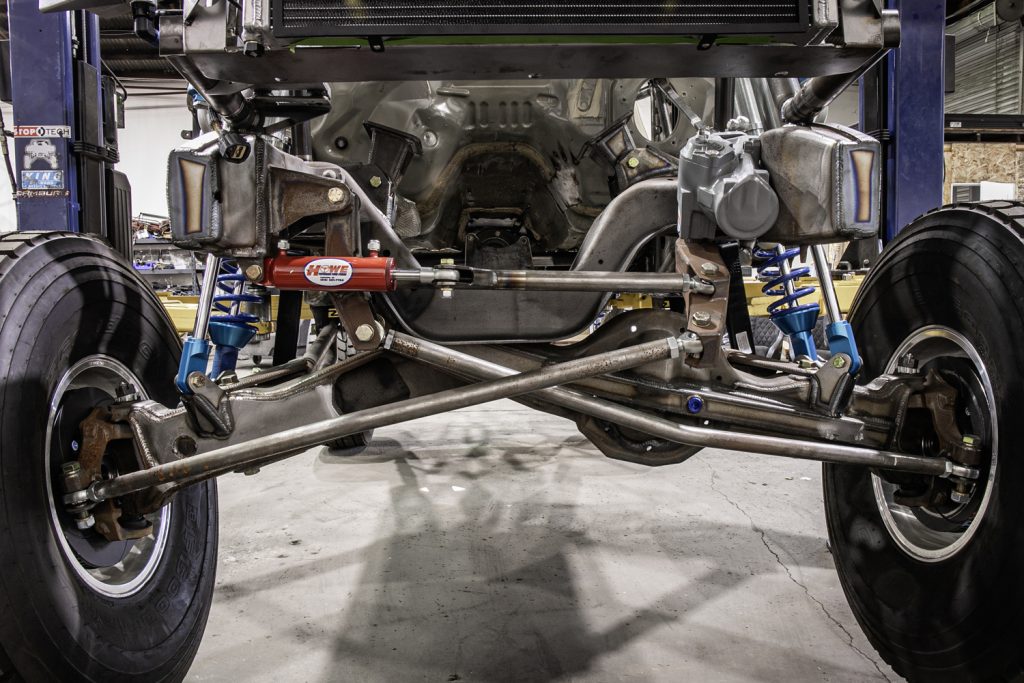

The Dana 44 TTB (Dana 44 Extended Beams +4.5″ from Solo Motorsports) is out of a 94 Ford Bronco (5th Gen Ford Bronco). Take a look at Solo Motorsports for more information on TTB kits and TTB steering kits. RCV axles are the plan but they have not been mounted yet. Anything could change before the truck heads off to SEMA. Stew wanted to keep the Toyota 6×5.5” bolt pattern for the KMC Impact beadlocks so the hubs are from a mid-80s 4×4 Chevy truck.

Steering

The steering is a single-swing kit from Solo Motorsports for the Ford Bronco & F-150. The physical steering box came out of a stock Bronco and was then sent off to Howe for a full revamp; tapped for hydro assist and rebuilt to match the increased flow from the modified Hellcat power steering pump.

Braking

The front brakes are a conversion kit from Solo Motorsports. It’s a bolt-on upgrade for a Wilwood 6-piston caliper, and 14″ 2-piece rotors. The rear features 2 4-piston Wilwood calipers per wheel, and 14″ 2-piece rotors. One caliper is for the primary brakes and the other is for the handbrake.

Front Suspension

TTB front, KING 2.5″ X 12″ Coilovers, KING 3.0″ X 12″ 4-tube bypasses, KING 2.0″ Bump Stops, 13″ Kartek Limit Straps, all resulting in 17″ of travel. The front beams were cut and extended 4.5″ by Solo Motorsports (Dana 44 Extended Beams Stage 5) along with their extended tubular radius arms.

The front shock mount’s main support and engine cage were fully designed with a mix of 3/16″ plate steel and 2″ .120 wall DOM. An engine cross brace spanned the width of the engine cage and was finished with 10 gauge underlays.

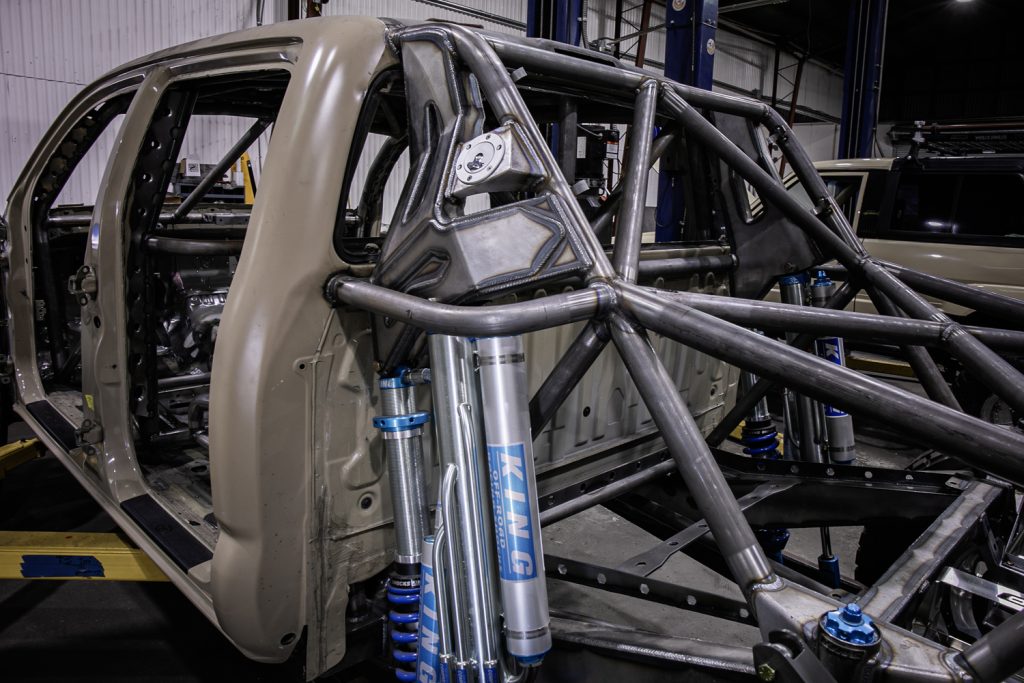

Rear Suspension

KING 2.5″ X 16″ Coilover, KING 3.5″ X 18″ 5-tube bypass (2 rebound and 3 compression), and KING 2.5″ bump stops. The sway bar arms are Eversen Performance Anodized billet 18″ with aluminum end links. The sway bar is a custom-made 4340 Chromoly 35 Spline 1.5″ sway bar from Sway-A-Way Technologies. The rear is finished off with 26″ Kartek Limit straps, bumped and strapped equaling to 26″ of travel.

For the rear upper shock mounts, CJ utilized the same boxed 3/16″ plate steel design as the front, incorporating welded sealed cutouts as a unique design element for the side profile, and fabricated a bracket to house the filler neck for the Fuel Safe fuel cell.

Rear Links

For links, it’s running the Solo Motorsports Tacoma triangulated 4-link kit with trailing arms.

Rear Axle

- Currie Fab 9″ housing

- Strange Engineering Ford 9″ 3rd member

- 4.56 gears spooled (full-time locker)

- Currie 40-spline shafts, Currie hubs, and drive plates

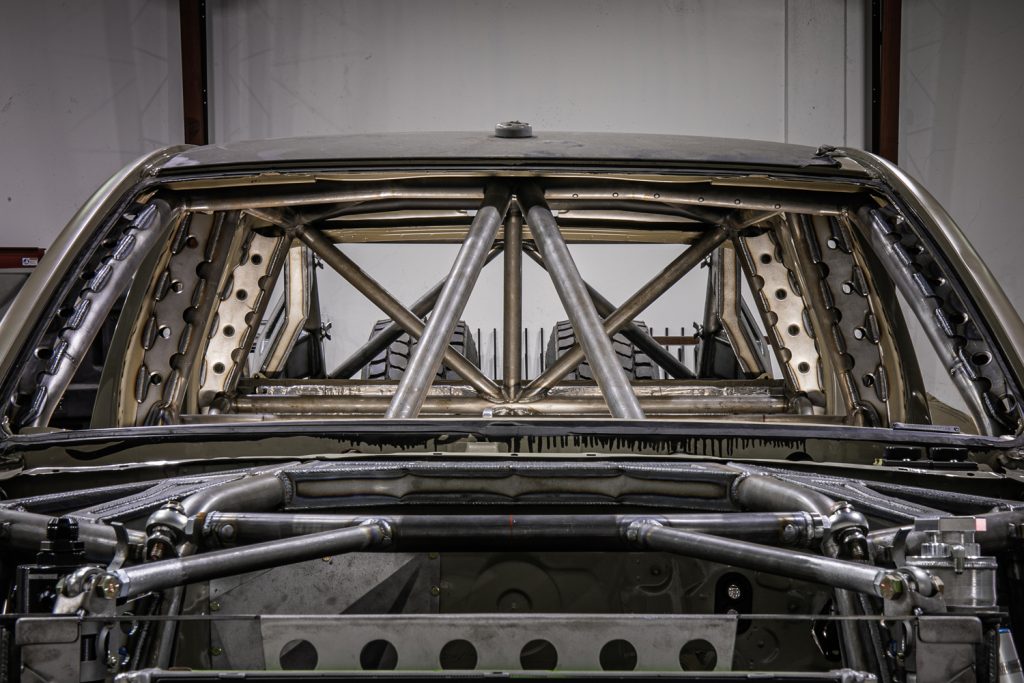

Roll Cage

The fab work, design, and creativity on this truck are something we all dream of. CJ mig-welded a full DOM cage with various tube sizing. The main structure of the cage (A-pillar, B-Pillar, and C-Pillar) are all 2″ x .120” wall DOM with 14 gauge dimple die plates while the remaining supports (diagonals, harness bars, and dash/windshield bars) are all 1.75″ .120 wall DOM. To finish off the interior cage while keeping interior space in mind, seat mounts and door bars were built out 1.5″ x .120 DOM. The smaller size DOM was used to save as much space as possible.

Interior Fab

In addition to the roll cage, an extensive amount of detail was given to items such as removable seat mounts for ease of carpet installation and service, custom steering column mounts using 10 gauge dimple died plates, mounts for the Vintage Air AC system (all to be hidden under the future carbon fiber dash), rear bench seat pivots via one center latch assisted by gas struts, center pedestal mount for locating the Hellcat shifter, the KibbeTech hydraulic hand brake, the behemoth twin transfer case sticks, a custom Stellar Built dash mount and much more.

Motor Cage

The motor cage was built with 1.75″ 120 wall DOM and 3/16″ plate steel. It attaches at 4 points through the firewall sheet metal directly into the front of the roll cage.

Core Support

The core support is a fully modular structure designed to be easily disconnected via two bottom interlocking tube clamps and two 5/8″ heim joints. CJ designed the entire core support for quick and convenient service. The core support houses all the heat exchangers and radiators for the vehicle; the engine radiator (CBR radiator full aluminum with two 12″ SPAL electric fans), heat exchanger for the Hellcat Supercharger (Mishimoto), AC condenser (Vintage Air), and finally an Auxiliary power steering cooler mounted to the side (CBR Radiators).

I had the luxury of watching CJ build the majority of this truck down at Stellar Built and the level of detail that went into the core support was unreal.

Back Half

For the back half of the build, CJ welded .120 wall DOM frenched to the roll cage above and below the rear window. The main structure of the back half utilized 2″ .120 wall DOM and then 1.75″ .120 wall DOM throughout the side of the frame (diagonals and crossbars). CJ started the back half by grafting custom-made CNC cut frame rails out of 1/4″ steel designed and cut in-house at Stellar Built. That newly built portion of the frame then connected to the back half of the cage and ultimately to the 2″ .120 wall DOM.

Fuel Cell

The full cell is a 60-gallon Fuel Safe Systems Enduro Cell. A lower perimeter frame was designed to locate it in the chassis to hold the cell, and finally, a CNC-cut top plate was fabricated in-house at Stellar Built to hold it in place.

Tires & Wheels

BFG Projects and KMC Impact beadlocks are currently planned, but this could all change before the SEMA debut.

Fabricator Spotlight

Since birth, C.J. has been immersed in car and truck culture. Growing up in the deserts of Southern California, it was inevitable that he would develop an interest in off-roading. He began driving his grandpa’s Jeep at the age of 4 and was introduced to welding at 12. These two interests eventually merged during high school. After graduating from Wyotech in 2011 with a specialization in chassis fabrication, C.J. channeled his passion into his personal vehicles, starting with building various types of prerunners. His projects quickly evolved from crafting garage-fabricated bumpers and bolt-on suspension parts to creating detailed roll cages and intricate chassis components.

Years later, C.J.’s journey culminated at Stellar Built, where he was given the opportunity to complete Stewart’s Meso Hellcat Tacoma. This project was a first of its kind for him and was executed with exceptional precision and thoughtful design. With innovative shock mount designs and form-fitting tube work, the project showcases the high level of craftsmanship involved. We eagerly anticipate seeing what future projects C.J. and Stellar Built will undertake following Stewart’s Helltaco.

Final Thoughts

The Lunar Rock paint to sample on the interior cage and cab starting to come together.

Insane build.

Lol, is this build even a Taco anymore?

Barely! More so in spirit… haha

Unreal. Last time I saw this truck it was getting close to this point. I remember when it first rolled in! Stoked to see the final form. Maybe Meso will let me drive it! Lol.

Can’t wait to see this 4 door trophy truck never go off-road

Stewart is not one to just let a truck sit. At every stage of this truck, he has pushed it so hard that the motor blows. So yeah, we will see this truck get tossed around.

So custom fiberglass everything?? Who’s doing all that. Can’t imagine stew is making every panel by hand or something. The hood, wide body panels… all in time for SEMA. GOOD LUCK. I’m on your side, and I hope you make it but that seems impossible.

Yeah, Stew is doing all the glass work by hand. He’s been working on it while the truck was being built. He’s been down at Stellar taking measurements of everything and rough fitting panels for the last few months. It is a ton of work but seeing how most of the panels are already formed, I think he will make it for SEMA. If you follow him on IG, you can see progress on his stories.